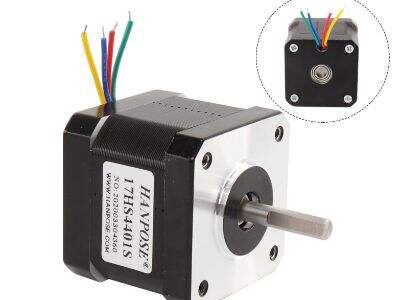

Ever been curious about how CNC machines work? They employ a specific part, called a stepper motor, for controlling movement and performing accurate cuts. In part two of this blog live series, we will look into how these motors can be made even more suitable for your CNC machining applications. Stepper Motors are Everywhere There’s really no better time to dig into the world of stepper motors.

Learn more about stepper motors in CNC machines.

Think of stepper motors as the muscles of the CNC machine. They inch the various parts of the machine forward in precise incremental moves to elaborate designs. These motors operate by following instructions ordered by the CNC controller to tell them how far to move and in which direction. In a sense, they are a robot on autopilot carrying out a set of rules to get a job done.

Preparing your Stepper Motors for the best performance and quality.

You must configure the Stepper Motor settings to get the best performance out of your CNC machine. This could be a modification of the number of steps per revolution, acceleration, top speed, etc. With the fact that these can be fine-tuned, it is possible to get the ideal combination of precision and speed. This is vital to putting the fine details as you cut out your work.

It may allow for fine-tuning of the stepper motor control in order to lessen the vibration and noise.

Stepper Motor that move too fast or too hard can produce unwanted vibrations and noise. This not only impacts the quality of cuts you receive, but also may wear down the machine after awhile. You can decrease the vibration and noise of the motors by change the motor control parameter, so that makes the cutting operation become smoother and quieter. Not only does this result in a higher quality of work, but it will also increase the life of your CNC machine.

With most efficient software to download and preference firmware support.

In the modern digital era, technology has a direct and substantial impact on maximizing the performance of the Nema Stepper Motor. There are software programs out there that can help you make some finer adjustments to your motor settings. With software such as HANPOSE CNC software, you can customise profiles for all your stepper motors and monitor performance in real time and make adjustments on the fly. All these functions provide to the machine more possibilities and can definitely improve your operation with your CNC machine.

Working out typical problems for the best performance from the stepper motor.

Despite all the great settings and firmware, all machines with stepper motors can have problems from time to time. Common issues are skipping steps, getting too hot, and mechanical poopage. Well, with some know-how, you should be able to troubleshoot and get your stepper motors back easily. Keeping your equipment well-maintained, properly lubricated and closely monitoring performance indicators can help you catch trouble early and avoid some costly downtime.

Table of Contents

- Learn more about stepper motors in CNC machines.

- Preparing your Stepper Motors for the best performance and quality.

- It may allow for fine-tuning of the stepper motor control in order to lessen the vibration and noise.

- With most efficient software to download and preference firmware support.

- Working out typical problems for the best performance from the stepper motor.