Stepper motors are useful in the control machines, robots and other systems. To actually move them, though, we'll need stepper motor controllers! These controllers ensure that the motors move in the right way at the right moment.

How stepper motor controllers work Stepper motor controllers work like the brain of the stepper motor. They're the ones that issue the motor commands as to where and how to move." It is essential since it is the thing that helps the motor to move accurately while stopping in the right position all the time. Without the stepper motor driver, the motor would just to know where to go or when to stop going there!

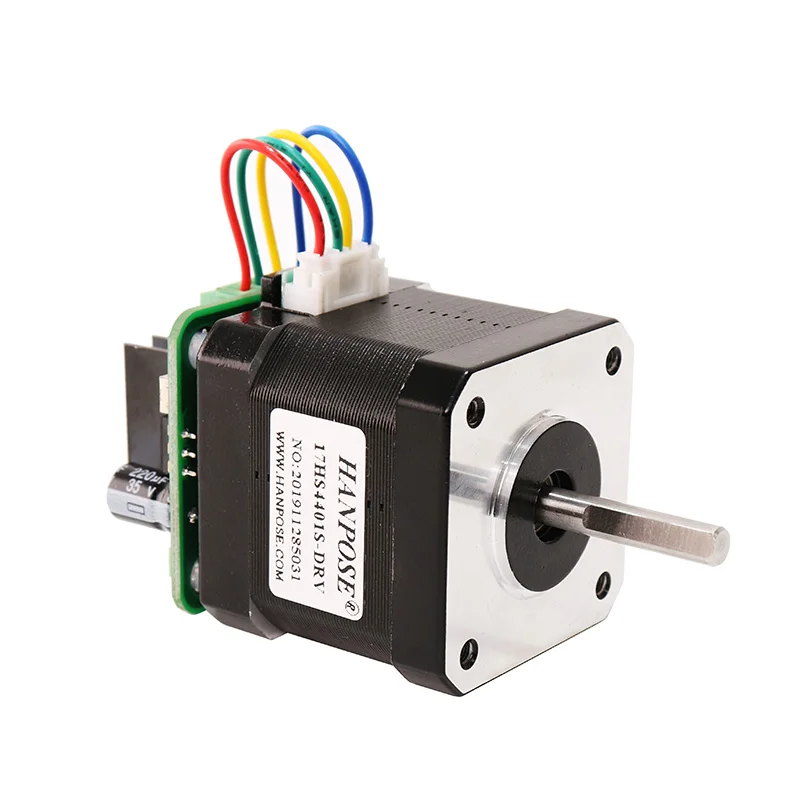

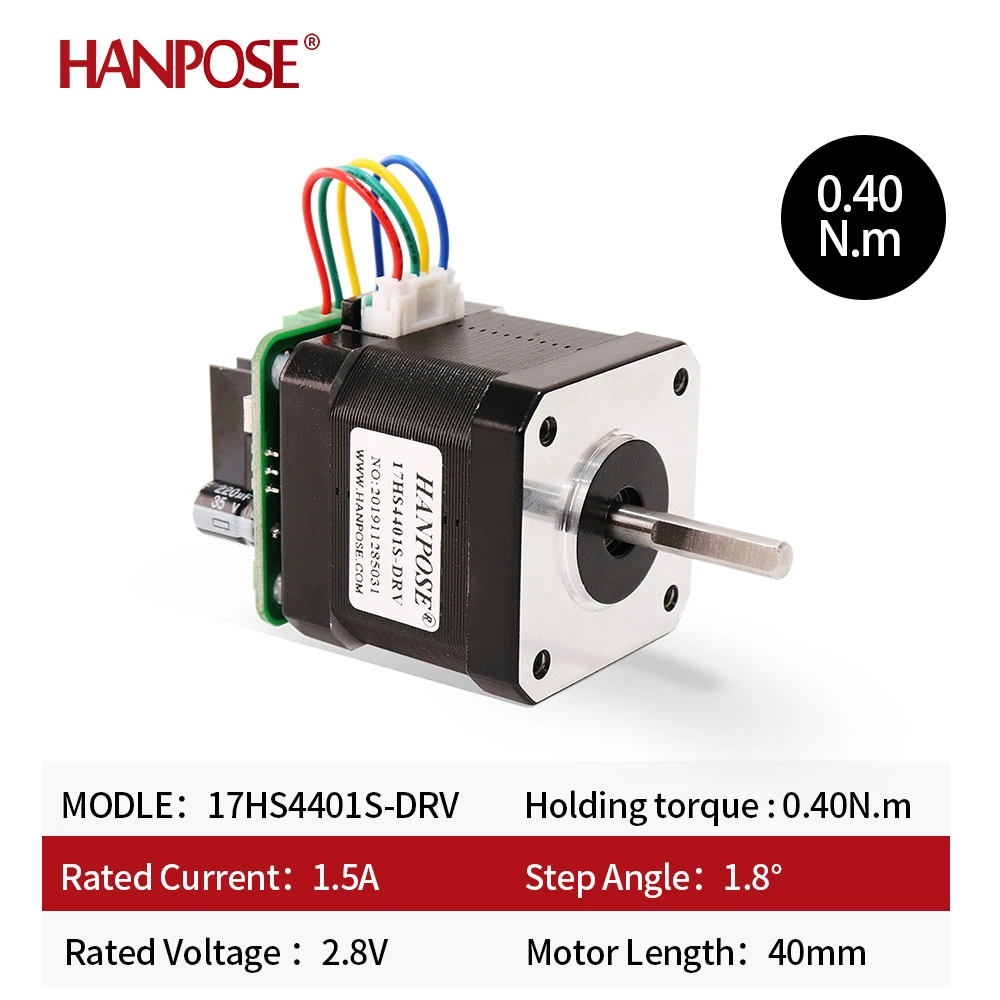

How the stepper motor controllers do it They have an electronic control chip inside them that generates electrical current flow in the motor to make it move. Signals like these let the motor know how far it needs to move and which direction to move. In sending a sequence of signals, the controller is able to cause the motor to move incrementally and precisely to the desired position. This can be useful in 3Dprinting, CNC and other precision applications such as a robot.

There are various kind of stepper motor controllers and each has its own good points. Some are very no-frills and intuitive to use, while others are technically more advanced units that provide an overall better experience. Selecting a stepper motor controller The specific requirements of the project and the necessary precision will help you decide what type of motor to choose.

Occasionally, stepper motor controllers fail, I have seen them not move the motor right, and heard weird noises from them. You see, one common problem is overheating, which could have been a result of too much current passing throught he controller. If you want to deal with this issue, you can lower the current or increase the number of cooling fans. It is crucial that these problems be resolved promptly so that the motor continues to experience good performance.

Stepper Motor Controllers Continue to Evolve Along with Technology And new features like wireless control and automatic calibration are helping to make stepper motors more approachable and efficient. Perhaps in the future we will see further improvements in stepper motor controllers that will make them even more efficient when it comes to controlling motors for a large variety of applications.